Bel-Ray® Food-Grade Lubricants: Eliminating The Choice Between Compliance And Operational Efficiency For Beverage Plants

Bel-Ray® No-Tox®: The Specialized Solution for Bakery Chains

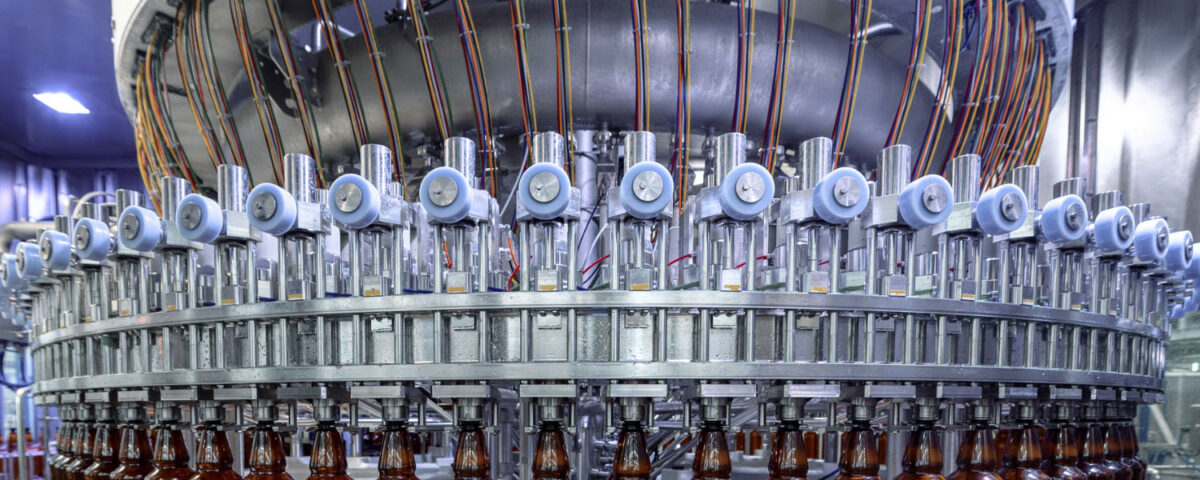

October 27, 2025The intense operating environment of a beverage plant subjects essential hydraulic and pneumatic systems—the workhorses of bottling, filling, and packaging lines—to extreme operational stress. Maintaining performance while ensuring product safety requires NSF H1 lubricants that meet strict regulatory and operational standards. Bel-Ray® synthetic food-grade oils are specifically designed to meet these challenges.

The Critical Challenges Of Lubrication In Beverage Plants

The hydraulic and pneumatic systems and lubricants essential to beverage production face five common stressors that can lead to equipment failure, significant downtime, and dangerous contamination.

- High Contamination Risk

As machinery operates near open containers, lubricants must be NSF H1-certified for incidental, unavoidable product contact. Furthermore, quality systems like HACCP, GFSI, and BRCGS require complete traceability and documentation for all lubricants used.

- Degradation From Harsh Washdowns

Beverage facilities rely on frequent sanitization using high pressure, high temperatures, and strong chemicals. This environment aggressively removes lubricant film and degrades seal materials. Chemicals in Clean-in-Place (CIP) systems actively damage lubricants, leading to rapid washout and relubrication frequency.

- Extreme Temperature Swings

Processing involves wide thermal ranges. Hydraulic systems must function reliably in cold zones (refrigeration and storage) and hot zones (pasteurization and sterilization). Lubricants must maintain consistent viscosity stability, resisting thickening in the cold or thinning in the heat.

- Material And Seal Compatibility

Seals, hoses, and gaskets in hydraulic units are constantly exposed to temperature swings, wet and dry cycles, and various cleaning chemicals. Using an incompatible lubricant can cause the seal materials to degrade, swell, or crack. This can lead to leakage, which poses a contamination risk and potential hydraulic-system failure.

- The Performance Trade-Off

Historically, food-grade lubricants often lacked the antiwear and extreme-pressure performance of industrial-grade products. This forced maintenance operators to choose compliance over operational efficiency, but this is no longer the case.

Bel-Ray® No-Tox® Syntra: Compliance Meets Performance

Bel-Ray No-Tox Syntra Food Grade Synthetic Oil (PAO) is a premium NSF H1-certified lubricant that eliminates the need to compromise on equipment performance. No-Tox Syntra oil offers complete regulatory compliance and unbeatable lubrication performance.

Regulatory And Safety Assurance

No-Tox Syntra is formulated for global acceptance. It is not only NSF H1-registered, but also Kosher and Pareve–approved and Halal–certified. Bel-Ray utilizes superior filtration processes compared to many competitors. It filters through a 2-micron filter system to achieve the highest cleanliness standards, reducing contamination risk and unnecessary wear in critical machinery.

Superior Synthetic Stability

As a synthetic polyalphaolefin (PAO) oil, No-Tox Syntra provides exceptional operational benefits.

- Exceptional Antiwear, Rust And Corrosion Protection: It is formulated with the highest quality synthetic oils and food-grade additives to protect and extend equipment life.

- Temperature Reliability: The synthetic base ensures high oxidative stability across extreme ranges.

- Washout Resistance: It offers high washout and corrosion resistance necessary to withstand constant chemical and water exposure in wet environments.

Component Integrity

No-Tox Syntra oil is formulated for compatibility with common food-industry elastomers and seals. This prevents the lubricant from causing swelling, cracking, or premature gasket failure: a key cause of leakage and contamination in hydraulic units.

Bel-Ray No-Tox Syntra Food Grade Synthetic Oil solves the maintenance challenges in beverage plants by delivering superior antiwear protection and extreme-temperature stability while ensuring compliance with the most rigorous global food-safety standards. This allows beverage manufacturers to maximize operational efficiency and safeguard product integrity simultaneously.

Contact our team to learn more.