Super Clean Chain Lube

Where Would We Be Without Waterproof Grease?

February 20, 2019

Why use Bel-Ray Motorcycle Oil?

February 21, 2019Take a look at the final drive of any high performance racing motorcycle and you will see a chain drive.A chain and sprocket drive offers the advantages of highly mobile rear suspension, changeable gearing and a lightweight rear hub. The chain is a very important link of the machine and if it is not maintained properly, there can be a measurable loss of performance in the final drive.

Even though we say a chain requires maintenance, the most important form of maintenance needed is simply proper application of a high quality chain lube. Friction and corrosion are a chain’s worse enemies and the cause of failure, noise and power loss. All this can be overcome with a little knowledge on chain lubrication and the right product.

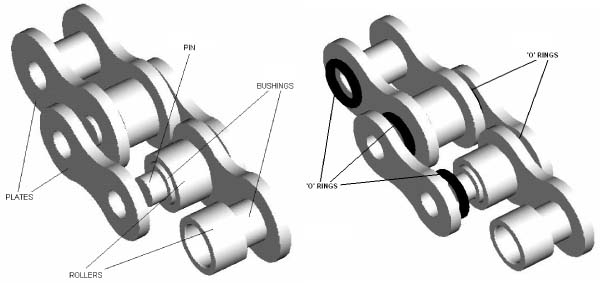

CHAINS 101:In motorcycles and ATVs, there are two basic chain types: standard (non- ‘O’ ring) chains and ‘O’ ring chains. The standard chain consists of side plates, pins, bushings and rollers. The ‘O’ ring chain is identical to the standard chain in construction except it utilizes rubber seals as shown in the diagram below:

| STANDARD CHAIN | ‘O’ RING CHAIN |

PLATES:The plates are the most visible component of the chain. They come in pairs of inner plates and outer plates and hold the entire load in tension.

PINS AND BUSHINGS:

Solid pins are pressed into the outer plates to hold them together, while the hollow bushings hold the inner plates together in a similar fashion. The pins from an outer link run through the bushings from the next inner link to form a chain. This junction is where the links are free to rotate relative to each other and it is a very important lubrication point. A well lubricated pin/bushing interface will allow a chain to spin freely on the sprockets and minimize the power losses due to friction. A poorly lubricated pin/bushing interface will result in wear that causes “chain stretch” to occur. The term “chain stretch” refers to the increase in overall length of the chain due to wear on the pins. As the pins and bushings wear, each pin is able to sit a little bit deeper on the next bushing. Multiply this small amount of wear by the number of links and you have a considerable change in overall chain length.

ROLLERS:

The rollers of the chain are the next piece to the puzzle. These are the cylindrical rollers around each bushing that make contact with the sprockets. These bushings spin on the outer surface of the hollow bushings and require lubrication underneath them for minimal resistance and wear, as well as a film on the outside to cushion the shock load when in contact with the sprocket.

‘O’RINGS (X-RINGS OR T-RINGS):

Sealed chains are common equipment on many motorcycles and ATVs. On these chains, rubber rings are put in between the plates of the chain as the seals. The chain will come from the manufacturer with lubricant in the pin and bushing area and the seals work to keep the original lubricant in and the harmful elements out.

STANDARD CHAIN VS. ‘O’ RING CHAIN:

Since the anatomy of the two types of power transmission chains is now understood, it is time to look at the applications of each.

| TYPE | CHARACTERISTICS | APPLICATION |

| Standard Chain | Minimal rolling resistance when properly maintained. Requires frequent cleanings and lubrications. Shorter life than ‘O’ ring chain | Racing |

| ‘O’ Ring Chain | Much more reliable and longer lasting. Less maintenance compared to standard chain. Slightly higher rolling resistance due to friction in the ‘O’ rings | All non-racing applications with street bikes, dirt bikes and ATVs or whenever reliability is desired |

Since the primary lubricant is already sealed inside the bushings of an ‘O’ ring chain, lubrication demands differ significantly between the two types chains. Bel-Ray Super Clean Chain Lube was designed to be the ultimate ‘O’ ring chain lube.

CHAIN LUBRICATION BASICS:

A major challenge that chain lubes must address is there is not an available sump to hold lubricant and continually supply it to the chain. This means

that once the chain lube is applied to the chain, it must stay in place. It must also be able

Bel-Ray’s German distributor, Meneks, developed this machine that simulates a spinning chain drive. The chain is warmed up, coated with Bel-Ray Super Clean Chain Lube, and allowed to dry. It is then run at speeds in excess of 300kph (186+mph.) The gears are enclosed in a clear, plexiglass case that will show any “fling off”—but to the amazement of the viewer, nothing flings off. This proves the effectiveness of Bel-Ray Super Clean Chain Lube at remainingon the chain, where it belongs.

to fend off all the elements that try to remove it from the chain. Possible threats to a lubricant can be dirt carrying it away, washout by water, and most significantly, thrown from the chain by centrifugal forces.

One thing that will work against a chain lubricant at all times is centrifugal forces. The spinning of the chain around the sprockets causes most chain lubricants to migrate to the outer surfaces of the chain, leaving critical areas unprotected from friction and corrosion. When this occurs, all of the soon to be mentioned lubrication properties are no longer of any importance. Once on the outer edge of the chain, many of these lubricants will then “fling-off” the chain onto fenders, swing arms and leathers.

Chain wax is one attempt to solve this problem, but it is not so efficient. Wax type lubricants have some good features for ‘O’ ring chain lubrication, however there are some significant drawbacks:

1. It cannot penetrate between the rollers and the bushings and typically the most good it can ever do is to keep the chain’s side plates from rusting.

2. The naturally occurring oils in waxes tend to evaporate, decreasing the already limited lubricating effect of the wax.

3. The tackiness of wax tends to attract dirt and grime to the chain. That is where Bel-Ray Super Clean comes in.

Bel-Ray Super Clean Chain Lube takes every benefit of the waxes and the best lubricating oils with the drawbacks engineered out. It was developed with a high vapor pressure solvent (evaporates quickly) that allows the lubricating chemicals to penetrate into the load carrying areas of the chain and spread out evenly on all surfaces. Once the solvent evaporates, the film takes on the coating characteristics of a slippery solid lubricant, creating a smooth, white coating around the chain. All one has to do is feel this film to notice the difference between it and a wax—and best of all, the film absolutely will not fling off, making sure that the chain will receive all the benefits needed from a chain lube.

Where Bel-Ray Super Clean Chain Lube excels is its ability to provide shock load cushioning and Extreme Pressure lubrication to the pivot points of the chain. Properly applied Bel-Ray Super Clean will coat the rollers inside and out. As sprocket teeth come in contact with the rollers, the white film and its solid lubricants provide maximum Extreme Pressure protection. This cushions the load and greatly reduces noise, sprocket wear and power-robbing friction. These lubricant properties of the Bel-Ray Super Clean film set it apart from any other chain lubricant.

Along with friction reduction, chain protection is one of the main reasons a chain lube is needed. Corrosion compromises the integrity of the metal which makes it the leading cause of chain failures. Bel-Ray Super Clean features the best corrosion protection of any chain lube available. It should be sprayed on all surfaces of the chain, including the side plates, to protect the metal from the environment. The slippery white film is engineered to resist water washout while repelling dirt and grime, keeping your chain free from damaging abrasives and looking “super clean.”

Quality packaging is another trait of an excellent chain lube. The pressure and pattern of the spray should be designed so the product goes where you want it. Poorly designed packaging will cause inadequate lubrication as well as be messy and wasteful. With Bel-Ray Super Clean, the package is designed to provide a spray pattern ideal for coating the chain.

Proper lubrication technique is vital to receive all the benefits that were just mentioned. The best method of applying chain lube is to spray the chain while it is still warm after a ride. This should be done on the inside of the chain near the back sprocket. It is important that the attached spray hose be used for proper spray pattern as well. Hold the tip one to two inches away and start spraying the outer side of the chain as you spin the rear wheel. Slowly traverse the spray with each revolution of the chain to coat both sides and the center of the chain. The chain is properly lubed after four (4) full revolutions of the chain are completed. The white color of Bel-Ray Super Clean Chain Lube makes it easy to see when the entire chain is coated.

CHAIN LUBE TESTING:

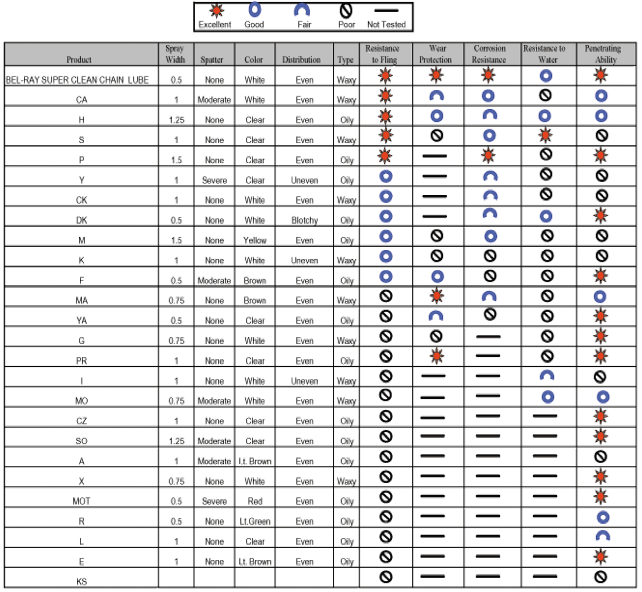

Extensive testing of chain lubes was done during the development of Bel-Ray Super Clean Chain Lube to ensure that it is the best performing ‘O’ Ring chain lube possible. Comparative testing of other chain lubes is done as well as a means of showing the advantages Super Clean holds over the competition. Bel-Ray Super Clean was designed and tested to outperform the competition in the following areas: Fling off resistance, film strength, penetration, corrosion protection, and water wash-out.

FLING-OFF TESTING

As mentioned earlier, resistance to fling off is a very important characteristic of a chain lube for more reasons than keeping your bike clean. Resistance to fling off represents the ability of a lube to stay in place and continue to lubricate the necessary chain components. In order to test for fling off, sections of lubricated chains were put on a sprocket. A bench test was made to spin the sprocket at a certain rate for a specified time inside of a large container lined with oil catching material. At the end of each test, the lining of the container was weighed to determine the amount of lube that was thrown from the chain. Also, the chain and sprocket were weighed very accurately to determine the amount of lube that stayed on the chain.

FALEX TEXTING

Upon hard acceleration, rollers and bushings see very high pressures when engaged with the sprocket teeth. This is where the extreme pressure (EP)

performance of a chain lube is put to test. In laboratory testing, the standard method of determining a lubricant’s extreme pressure ability is the Falex test. This involves spinning a pin between two blocks with an increasing load until failure occurs from lack of EP lubrication. A higher load at failure means the lubricant has higher EP performance.

PENETRATION TESTING

This test effectively shows the ability of the lubricant to penetrate the rollers of the chain. The depths of penetration given in the table show the relative abilities between all the products.

CORROSION TESTING

When a bike or ATV is ridden in wet conditions, moisture attacks the chain. If a chain lube does not provide the necessary corrosion protection, the chain could oxidize which will dramatically shorten the life of the chain and the sprockets. The corrosion test used to evaluate the chain lubes is the standard ASTM D665 test method of steel rods coated with chain lube and submerged in a salt water solution. The results fall in the categories of Pass, Light Rust, Moderate Rust, and Severe Rust.

WATER WASHOUT TEST

This water washout test represents the ability of the chain lube to stay in place while hit with a jet of water. A common problem with some chain lubricants is that they will be carried away by mud and water, which causes a decrease in lubrication and corrosion protection. The test is carried on for 2 hours and at the end, a percentage of the total lubricant is reported as wash-off.

TEST RESULTS

The test results are all summarized in the following spreadsheet. Most importantly, the Bel-Ray Super Clean Chain Lube tops all the competitors in resistance to fling off. When subjected to the fling-off test conditions, Super Clean proved it can stay in place better than any of the competition to provide long lasting lubrication and protection. Other categories where Bel-Ray topped the field were corrosion protection and extreme pressure lubrication, with strong results in water washout resistance and penetration.

THE BOTTON LINE:

Bel-Ray Super Clean Chain Lube is tested and proven for performance in all the different areas mentioned above. Bel-Ray Super Clean sets onto the chain with the appearance of a wax, but that is where the similarities end. The unique solid film lubricant stays in place through harsh environments and provides better lubrication under extreme stresses than any chain lube on the market. With proper application, Bel-Ray Super Clean Chain Lube will provide a long lasting, clean looking chain that requires fewer adjustments.

Download PDF Version:

Super Clean TR.pdf